CASE STUDY

SMART

CONDITION

MONITORING

Critical Data and Control Now

Available at Their FingertipS.

Vickers Aircraft required remote condition monitoring for curing carbon fibre. COGNETEX delivered a system that has become a critical part of the aircraft factory.

Measure

Anything

Improve

Decisions

Control

Remotely

"The system is now absolutely critical to our business. Without it we could not produce the carbon fibre with the tolerances required. It is

an essential monitoring and decision-making system for us."

Paul Vickers

Paul Vickers of Vickers Aircraft is an entrepreneur on a mission. With the Light Sport Aircraft (LSA) market set to explode with new innovations and aircraft, Paul and his team set out to build an amphibious aircraft that was fun and easy to fly, extremely light yet strong.

The Wave aircraft is a two-seater amphibious LSA with over 90% of its structure fabricated in ultra-light weight carbon fibre. The manufacture of carbon fibre components requires stringent process and temperature control.

“Around the 3000 m2 site occupied by Vickers Aircraft are a wide variety of high- tech machines including the carbon fibre curing ovens.

When curing our carbon fibre, we have to be very careful to maintain consistent times and temperatures. We had to rely on a staff member sitting and monitoring conditions, waiting for the oven to finish or to ensure the temperature did not drop or increase. If we left a component too long or the temperature dropped, we could lose thousands of dollars of carbon fibre.” says Paul.

With a small staff of around 10 people, freeing up time was important to moving the development of the aircraft forward. Further, problems could be missed by distracted staff causing delays and problems down the production line.

“We needed a system that could allow our people to do the job they needed to do, not monitor temperature or time.”

MONITORING CONDITIONS, ENABLING REMOTE CONTROL AND IMPROVING DECISION MAKING. PEACE OF MIND DELIVERED TO VICKERS AIRCRAFT.

Enter COGNETEX. Paul knew of Loop Technologies and approached Roger about the potential for the development of a solution to their problem. Roger, knowing of the potential for a technological solution, jumped at the chance.

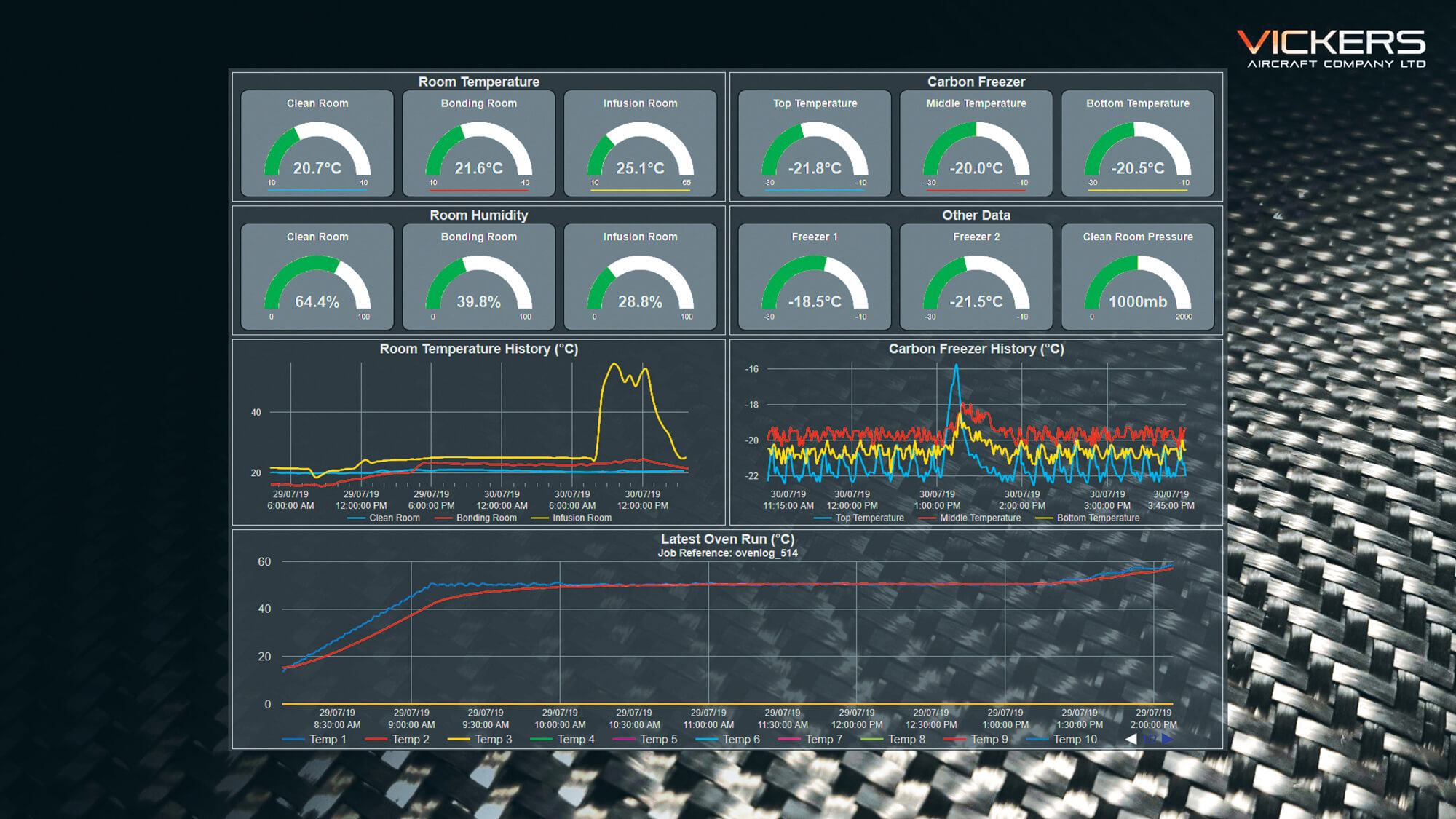

The first task was to allow Paul and his staff to monitor and control the curing oven. The COGNETEX team got to work developing a control system that would not only hold the temperature of the oven in close tolerance but would also allow Vickers staff to change the thermal profile as required. All of this needed to be able to be done from any desk in the office.

With an array of sensors built into the curing oven, the COGNETEX solution reflected the data collected into a custom developed LabVIEW application at anyone’s desk. Alarms were also built in to notify staff of any immediate changes in temperature or problems with the carbon.

“We needed a system that could allow our people to do the job they needed to do, not monitor temperature or time.”

Paul says; “Now we can have the whole company watching remotely, reacting quickly and in a timely manner. We have freed up our people resources with the use of technology.”

With the data available and monitoring taking place, the next step was to build an App for mobile devices. The App would allow the Vickers Aircraft team to monitor the ovens, freezers and factory remotely. Alarms alert them to any problems and they can action any remediation immediately.

“All our clean rooms are monitored for temperature and humidity as well as the ovens. All these things are critical to the final structure of the carbon. I can be anywhere and open the App and check in on the factory, if something goes wrong, I know about it within seconds. The peace of mind I gain from knowing that everything is as it should be is wonderful.”

THE BENEFITS GO BEYOND COOKING CARBON FIBRE. COMPONENT TRACEABILITY.

“Flawless and Effortless. Working with the COGNETEX team was brilliant. They understood what we needed and delivered more than we thought we wanted. Don’t look anywhere else.”