CASE STUDY

THE CONCEPTION

OF COGNETEX: An Origin Story

At the start of 2013, the Internet of Things (IoT) concept was just beginning to emerge into mainstream thinking.

Google was about to purchase Nest, the smart home automation company and buzz was growing throughout the electronics market of the possibilities of how different devices could automate and collect data to improve people’s homes and workplaces.

“The applications for the platform are endless. We can take any environment or machinery, develop ways to measure the critical data points with sensors and report that data in a way that is immediately useful to the user. The decision-making power is immense.”

In Hamilton, New Zealand, Loop Technologies were beginning to ask themselves questions about how they might improve their workplace. Glenn McCarthy, was Business Manager – Technical Solutions at the time and he reflects;

“We looked at our workplace, our lab area particularly, and asked ourselves; what can we measure and what do we need to have in place to collect data? In a facility like ours, where we deal with electronics every day, temperature monitoring of critical equipment was the obvious place to start.”

The importance of optimum temperature in a facility such as Loop Technologies cannot be overstated.

“We operate a lot of expensive equipment on a 24 /7 basis and if we have a cooling system failure, the temperature rise can be significant causing processors to overheat and severely shorten the life of the electronics. Some of the gear we operate is legacy equipment that is no longer available, so temperature is critical.” says Glenn.

Another important aspect that needed better monitoring, was the humidity of the work environment.

“We have a special coating on the floor of the lab to dissipate away static charge, and our team wear static protective coats and heel grounds to ensure that no unseen static electricity can damage the equipment we are working with. If the relative humidity is not above 30% these don’t work,” says Glenn.

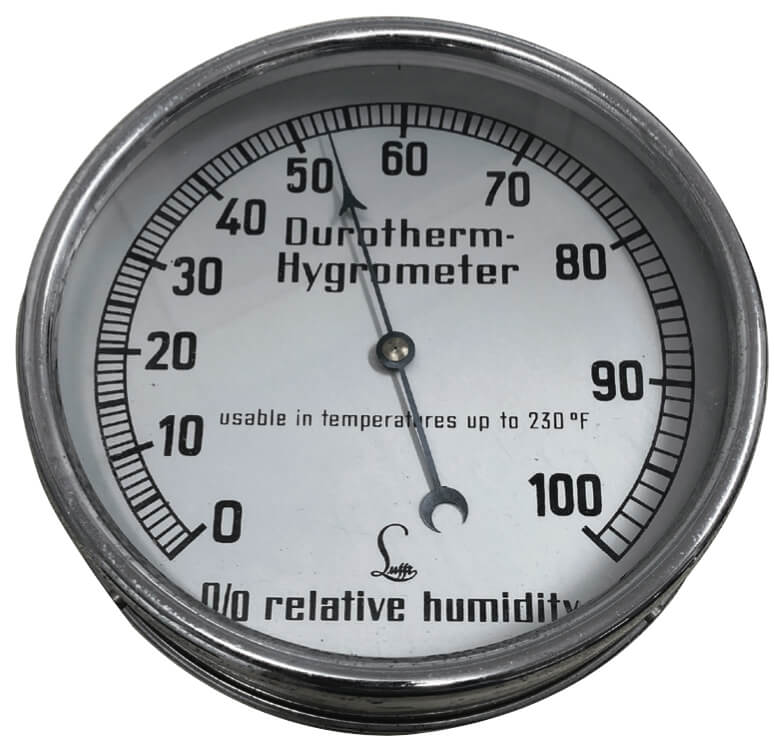

Humidity within the facility is measured using a hygrometer. The hygrometer measures water vapour in the air and displays it as relative humidity. A relative humidity of 30% or greater is required to ensure the team can safely work with the electronics. If the humidity falls below that level it is necessary to take additional static protection precautions. Walking past and checking the hygrometer was the only way to check the humidity levels.

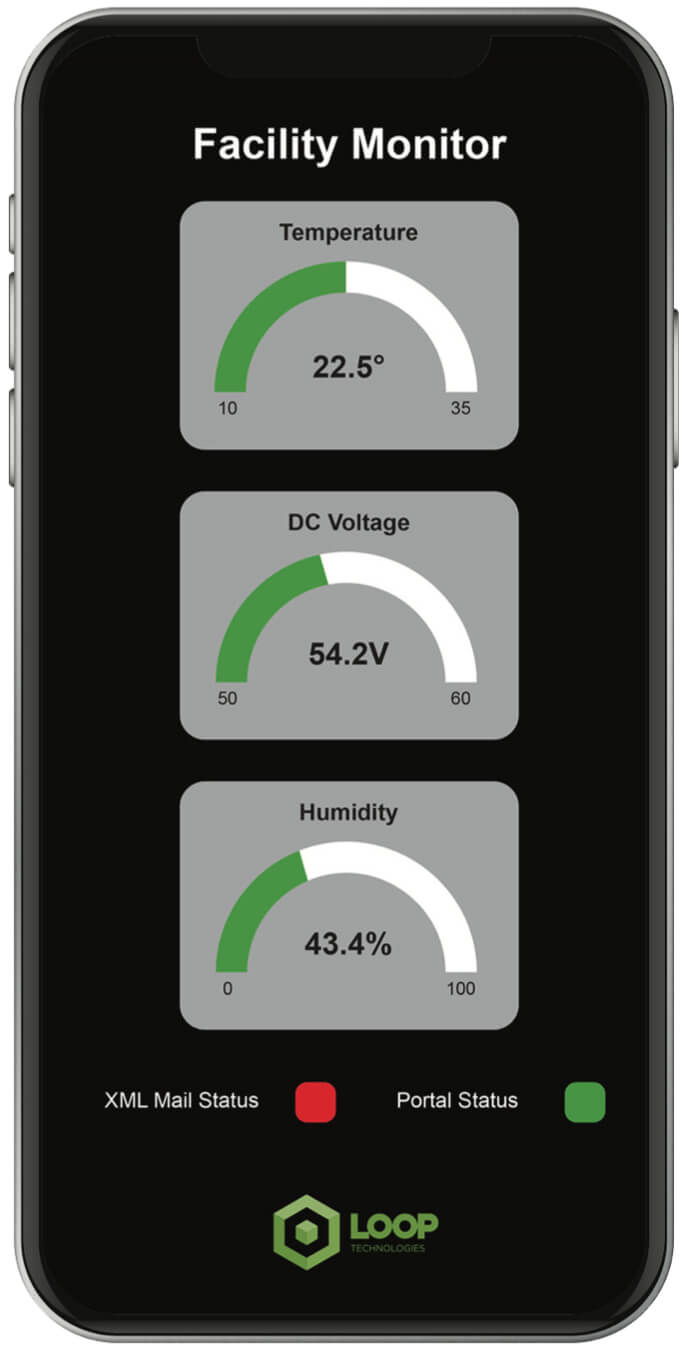

Temperature and humidity are both critical aspects of Loop’s business, so Glenn began to investigate possible solutions using IoT. He soon found temperature and humidity sensors could be brought together with a wireless embedded computer module to collect data and send it to the cloud. What he and his team then devised were the ways and means to store and display the data that could enable accurate and timely decisions to be made. The Loop team built computer software interfaces and a mobile app that enables the constant monitoring of the temperature and humidity levels within the facility.

The Loop team, now have 24/7 peace of mind that their critical equipment is not overheating and they no longer need to check the hygrometer every day. The system has alarms built into it so if there is a high temperature or drop in humidity the system will alert the team instantly. This enables the team to address any issues that may arise quickly.

Looking around the business, Glenn next zeroed in on the facility’s critical DC power supply. For many years, Loop has been the preferred supplier to several of the larger telecommunications companies for component level repair. The test beds used in the repair process require power supplies that stay within precise limits.

The team got to work developing the necessary technology to monitor the power supply and ensure it is always within the correct range.

“The IoT solution turned out to be incredibly useful and we soon found ourselves asking; where else could we apply this thinking and technology in our business?”

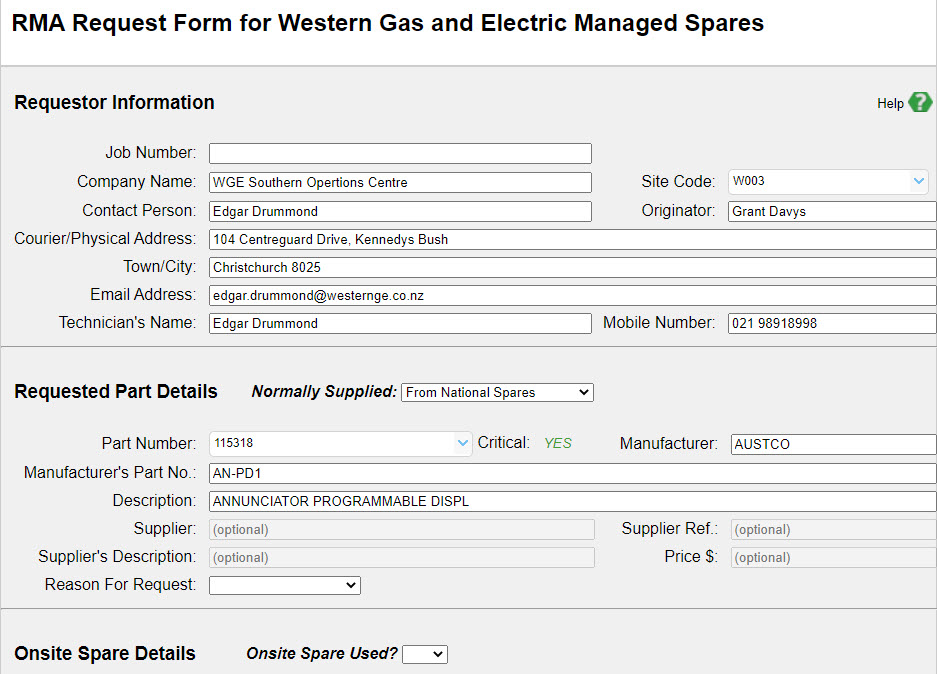

IoT ENABLES REAL-TIME SPARES MANAGEMENT PORTAL MONITORING

Loop Technologies operates a web portal which allows its customers to make spares requests online. It is necessary that this portal is always operational.

Glenn and the team implemented a clever method to continuously check that the system is working. They created a dummy request, which repeats every 10 minutes and is monitored by the cloud based system like a heartbeat. If the request is not received, alert emails and smartphone notifications are triggered immediately, meaning the issue can be fixed in a timely manner.

Glenn says; “We need to maintain the integrity of our online ordering system. The solution we built enables us to have confidence that the system works as it should all the time. And should a problem arise, we know that we are alerted to the issue immediately, rather than waiting for customer feedback.”

And for the Loop Technologies management team the peace of mind from knowing their system works to measure, monitor and control the environment within the Loop Technologies Lab and offices has been important.

“We now have certainty that we will be alerted should issues arise across the various environments and systems within the business. We do not need to worry about the humidity, the temperature or if the online spares ordering system is operational.”

COGNETEX : THE NEXT STEP IN IOT

With the technology successfully installed in their own lab, the Loop team began to look for other applications of the technology they had developed.

Roger Hurst, Director of Loop Technologies says; “With the knowledge and confidence we developed with our in-house IoT solution, we realised that we could implement this platform in a wide range of business situations. Our next customers, the Vickers Aircraft factory in Hamilton, and Tauranga City Council, demonstrated the diversity of use cases for the system we had developed, and the COGNETEX platform was born.”

And according to Glenn, “The COGNETEX platform is the chassis. We then add the extras to the chassis to get the system to measure whatever it is that needs to be measured.”

Loop’s Design Engineers design and manufacture the interface hardware to connect the sensors to the platform. From there our software developers build the apps and reports, extending the abilities of the IoT.

All-in-all the COGNETEX platform is a way for companies to benefit from IoT and the decision-making power it enables. Limited only by their imagination, the team at Loop and COGNETEX are excited by the possibilities and projects they are working on.

For their customers, the applications for the technology are only just beginning to be discovered, but judging by the projects currently being worked on by the COGNETEX team, the future for the application of the technology is bright.